Tecnologia

Encontrará informações sobre os nossos processos avançados de impressão, laminação, corte, confeção de bolsa e outras aplicações que garantem qualidade, inovação e sustentabilidade em cada produto.

A NOSSA TECNOLOGIA

IMPRESSÃO

IMPRESSÃO FLEXOGRÁFICA

Comexi F4

A Comexi F4 foi a primeira a incorporar os conceitos patenteados FLEXO Efficiency de ergonomia e acessibilidade, além de desempenho e robustez, que também são características de toda a gama de máquinas Comexi. É a solução perfeita para Impressão Flexográfica até 8 Cores, com Sistema AVT incorporado.

IMPRESSÃO DIGITAL

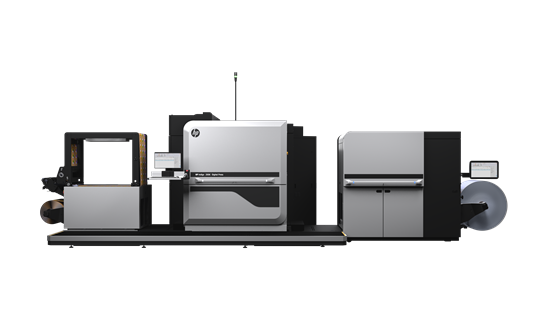

HP Indigo 200K

HP Indigo 200k, a última geração da tecnologia em impressão digital no mercado das embalagens flexíveis. Este equipamento é vocacionado pela sua versatilidade para lançamentos de produtos, campanhas de marketing, com pequenas quantidades, possibilitando a personalização bolsa a bolsa, com impressão de código de segurança, capacitada ainda para produção de sleeves. Elevada qualidade de impressão e resolução, não possui custo de gravuras/clichés, permitindo reduzidos prazos de entrega.

HP Indigo 25K

HP Indigo 25K, impressão digital no mercado das embalagens flexíveis. Este equipamento é vocacionado pela sua versatilidade para lançamentos de produtos, campanhas de marketing, com pequenas quantidades, possibilitando a personalização bolsa a bolsa, com impressão de código de segurança, capacitada ainda para produção de sleeves. Elevada qualidade de impressão e resolução, não possui custo de gravuras/clichés, permitindo reduzidos prazos de entrega.

HP Indigo 6K

A impressora digital HP Indigo 6K define o padrão da indústria para a produção de etiquetas digitais e shrink sleeves, oferecendo uma vasta gama de aplicações para atender às exigências das marcas mais inovadoras. Com recursos de alto valor, como proteção de marca (tinta invisível) e acabamentos especiais, maximizando a eficiência de produção e impulsionamento de novos produtos.

LAMINAÇÃO

LAMINAÇÃO

Comexi SL2

A Comexi SL2, face ao design que possui, permitem ao operador a facilidade de uso, em virtude dos seus controlos de última geração, tornando-a a laminadora ideal para pequenas e médias tiragens e para uma ampla variedade de materiais.

LAMINAÇÃO/VERNIZ

Comexi ML2

A Comexi ML2 oferece total versatilidade com vários tipos de aplicações nas embalagens flexíveis. Permite estruturas de 3 camadas, aplicações de vedação térmica, revestimentos de registo com vernizes mate e brilhantes, selagem a frio, laminagem com e sem solventes e muitas outras possibilidades, tudo em apenas uma laminadora.

CORTE

REBOBINAGEM

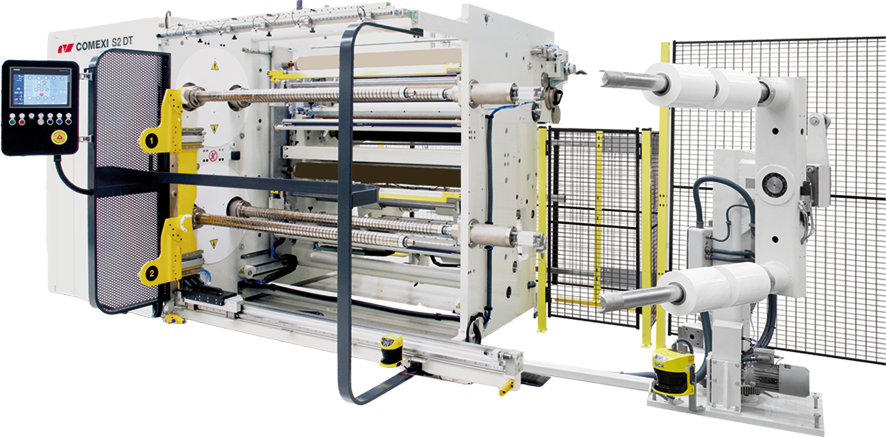

Comexi S2DT

A Comexi S2DT, é uma máquina multifuncional que corta a maioria das larguras de filmes usadas no mercado de embalagens flexíveis sem problemas, com uma taxa de produção muito alta, graças à sua saída de torre dupla.

REBOBINAGEM

Bimec STB 550

A STB 550 possui uma estrutura unilateral com capacidade de receber bobines-mãe com diâmetro até 1000 mm e cortar bobines acabados até 500 mm.

CONFEÇÃO DE BOLSAS

STAND UP POUCH

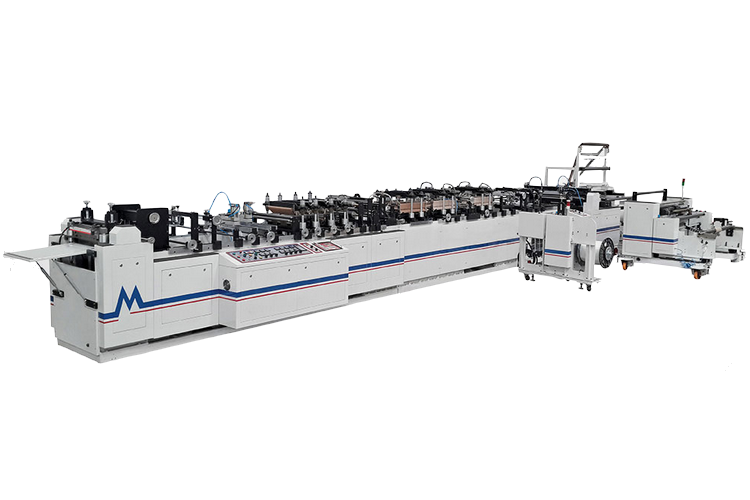

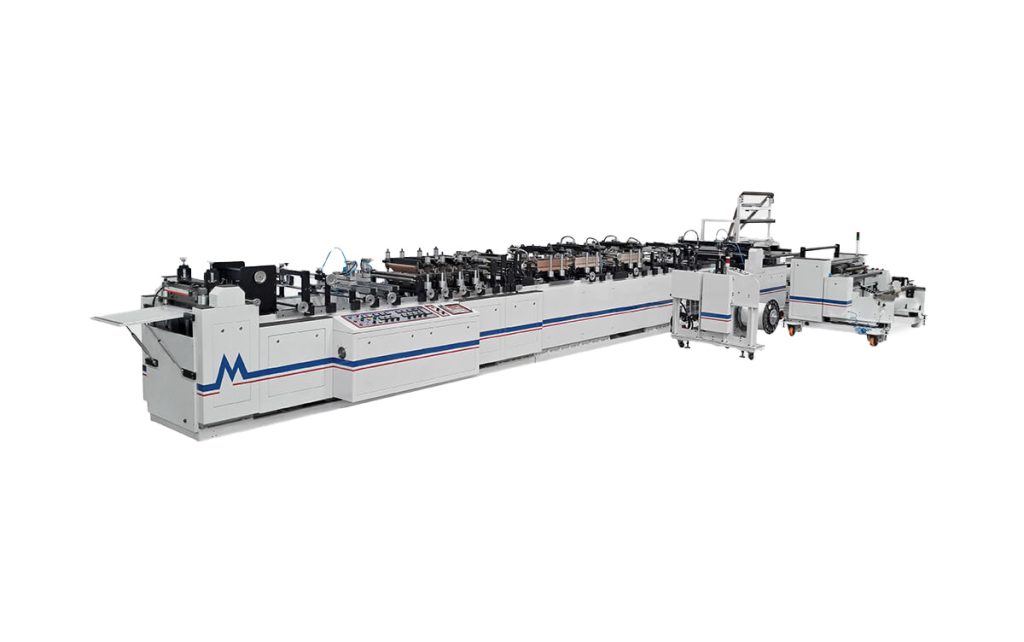

Mamata Win-500-PM

A Mamata Win-500-PM, é a máquina com uma combinação única de simplicidade, flexibilidade e desempenho. É o único fabricante de Sacos que tem flexibilidade para produzir não apenas Sacos com soldadura central, 2/3 Soldaduras laterais, mas também Sacos Doypack, com e sem Zip, na mesma plataforma.

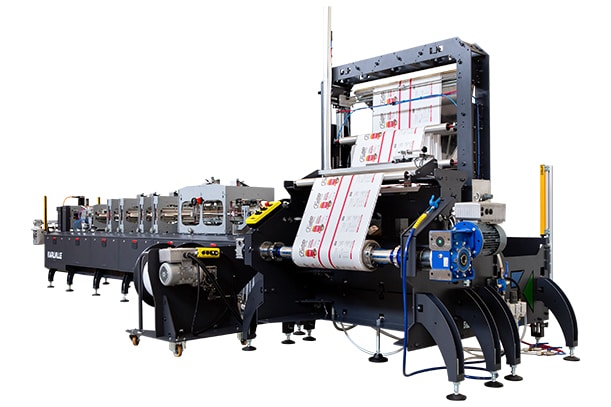

Karlville DSUP-400

Máquina compacta de bolsas concebida para digital e convencional, troca rápida, ideal para a produção de alto desempenho de tiragens curtas e médias para laminações standard, monomateriais e estruturas à base de papel.

Mamata Vega 285

O Vega 285-PM é especialmente concebido para fabricar bolsas com soldadura tripla lateral e stand-up pouches auto-reforçados em pista única a partir de laminados de PET/BOPP/Alu., etc. Com uma velocidade mecânica de 100 ciclos/minuto, é uma máquina simples, mas rápida para conversores com requisitos de fabrico em média escala.

PET FOOD

Mamata Win-610-PM

A Win-610-PM foi especialmente concebida tendo em mente as necessidades emergentes do mercado de processamento de filmes recicláveis e a elevada produtividade.

TIPO CAFÉ

Mamata Win-305-PM

Os sistemas de fabrico de bolsas oferece flexibilidade para fazer bolsas a partir de filmes Co-Ex não suportados, bolsas com filme impresso superior e inferior separados com controlo de registo.

BAG-IN-BOX

BIB 500 SL – TECNOCANTO

A BIB-500-SL, possui elevada versatilidade, realizando a soldadura das diferentes camadas de filme, colocando a boquilha e torneira, possuindo um registo de marcação de dados na bolsa, realizando o corte ou picotado para produção saco-a-saco ou em contínuo, tudo isto num processo totalmente automático. Sendo incorporada com 1 pista, realiza a produção de bolsas entre 3 a 20 Litros de capacidade.

SPOUTS

STAND UP SPOUTS

NCA1604C

Nesta máquina é feito o corto para soldar um spout de plástico a uma bolsa flexível.

É adequado para embalagens um pouco maiores de bebidas, geleias, molho de soja, aromas e cosméticos (leite, máscara facial) etc.

STAND UP SPOUTS

NCA1620B-25

Nesta máquina é feito o corta em ângulo e solda automaticamente um spout de plástico no stand up.

É adequado para grandes bolsas de bebidas, açúcar de uva em pó, líquido de lavagem, líquido para lavagem das mãos e cosméticos, etc.

SHRINK SLEEVE

SHRINK SLEEVE

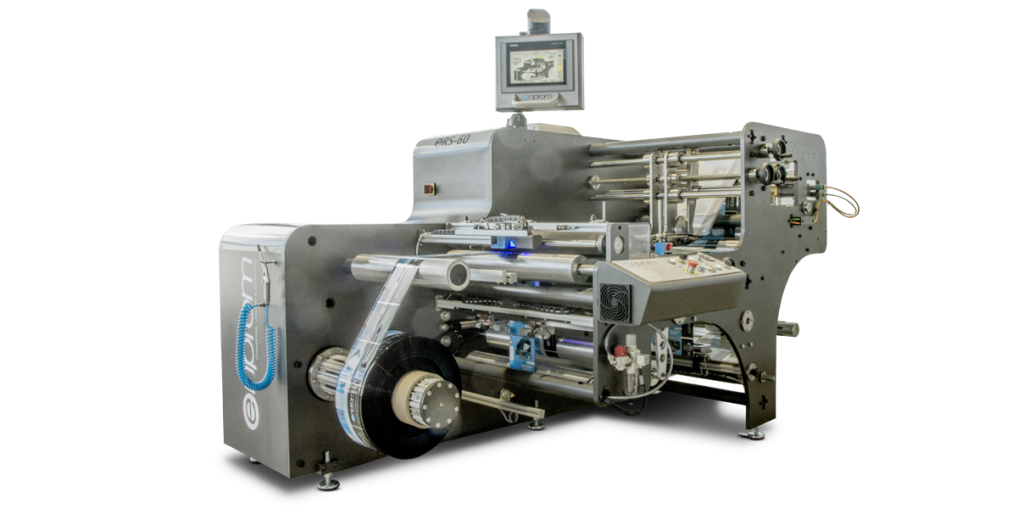

Enprom ERS-60

A Emprom ERS-60, é uma máquina de costura de manga termo-retrátil, que converte uma folha de plástico em uma etiqueta de manga única ou manga múltipla para embalagens promocionais, também denominadas de Sleeves. Este equipamento, garante uma soldagem constante e forte, para que não abra quando o calor é aplicado. A aplicação do adesivo permite uma soldagem plana e limpa.