Technology

Here you will find information about our advanced printing, lamination, cutting, pouch-making, and other applications that ensure quality, innovation, and sustainability in every product.

OUR TECHNOLOGY

PRINTING

FLEXOGRAPHIC PRINTING

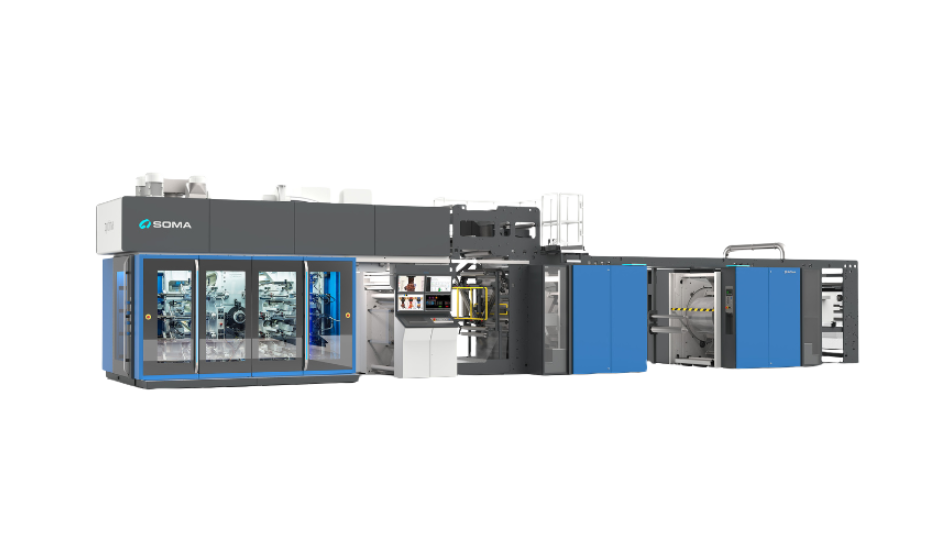

SOMA Optima 2

SOMA Optima 2 is a state-of-the-art flexographic printing press, positioned at the forefront of printing technology for flexible packaging. It combines high speed and a high level of automation with extremely fast job changeovers, minimising waste and ensuring exceptional accuracy in both large and short runs. With speeds of up to 600 m/min and multiple widths available, it incorporates advanced systems such as the Changeover Wizard, ARUN, and vibration control. Its modular structure and ergonomic design deliver maximum operational flexibility, efficiency, and ease of use, making it one of the most advanced and competitive solutions on the market.

Comexi F4

Comexi F4 was the first to incorporate the patented FLEXO Efficiency concepts of ergonomics and accessibility, along with the performance and robustness that characterise the entire range of Comexi machines. It is the perfect solution for flexographic printing of up to 8 colours, with an integrated AVT system

DIGITAL PRINTING

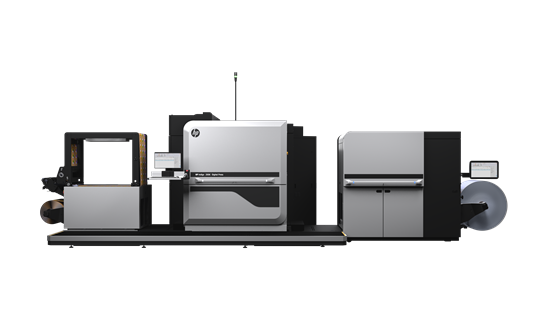

HP Indigo 200K

HP Indigo 200k, the latest generation of digital printing technology in the flexible packaging market. Designed for versatility, it is ideal for product launches, marketing campaigns, and small runs, enabling pouch-by-pouch customisation, security code printing, and even sleeve production. Offering high print quality and resolution, it eliminates plate and cylinder costs, allowing for reduced delivery times.

HP Indigo 25K

HP Indigo 25K, digital printing for the flexible packaging market. Designed for versatility, it is ideal for product launches, marketing campaigns, and small runs, enabling pouch-by-pouch customisation, security code printing, and even sleeve production. Offering high print quality and resolution, it eliminates plate and cylinder costs, allowing for reduced delivery times.

HP Indigo 6K

The HP Indigo 6K digital press sets the industry standard for digital label and shrink sleeve production, offering a wide range of applications to meet the demands of the most innovative brands. With high-value features such as brand protection (invisible ink) and special finishes, it maximises production efficiency and drives the launch of new products.

LAMINATION

LAMINATION

Comexi SL2

Comexi SL2 offers operators ease of use through its state-of-the-art controls, making it the ideal laminator for small and medium runs and for a wide variety of materials.

Comexi SL2 Evolution

The perfect combination of productivity, configuration and automation offering high versatility across a wide range of materials. SL2 Evolution is the leading option in solventless lamination and the only one that can work fully automated with Closed Loop.

LAMINATION & VARNISH

Comexi ML2

Comexi ML2 offers complete versatility with multiple application types for flexible packaging. It enables three-layer structures, heat-seal applications, registered coatings with matt and gloss varnishes, cold sealing, solvent-based and solventless lamination, and many other possibilities in a single laminator.

SLITTING

SLITTING

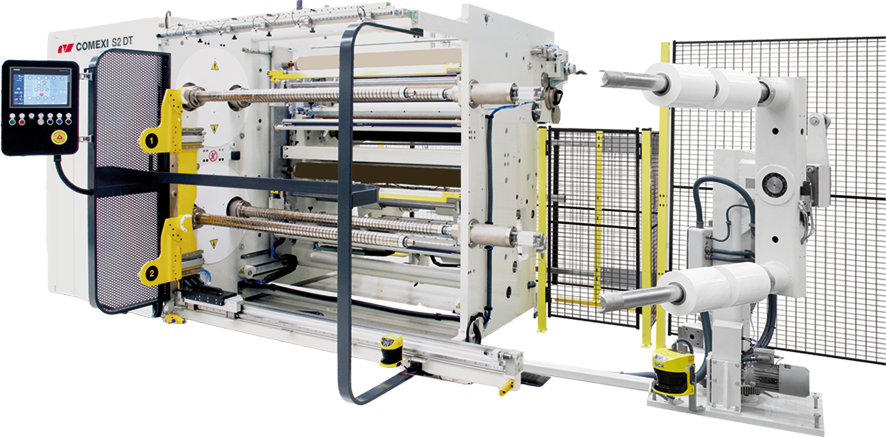

Comexi S2DT

Comexi S2DT is a multifunctional machine that effortlessly slits most film widths used in the flexible packaging market, delivering a very high production rate thanks to its dual-turret output.

SLITTING

Bimec STB 550

STB 550 has a single-sided structure, capable of handling parent rolls with a diameter of up to 1000 mm and slitting finished rolls of up to 500 mm.

POUCH-MAKING

STAND UP POUCH

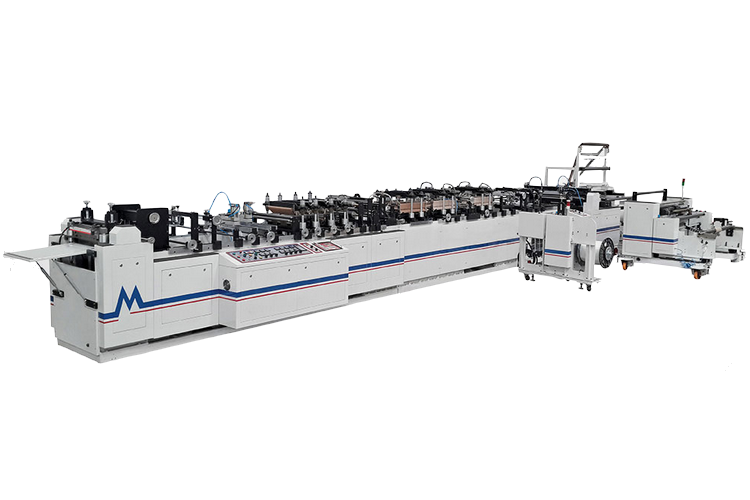

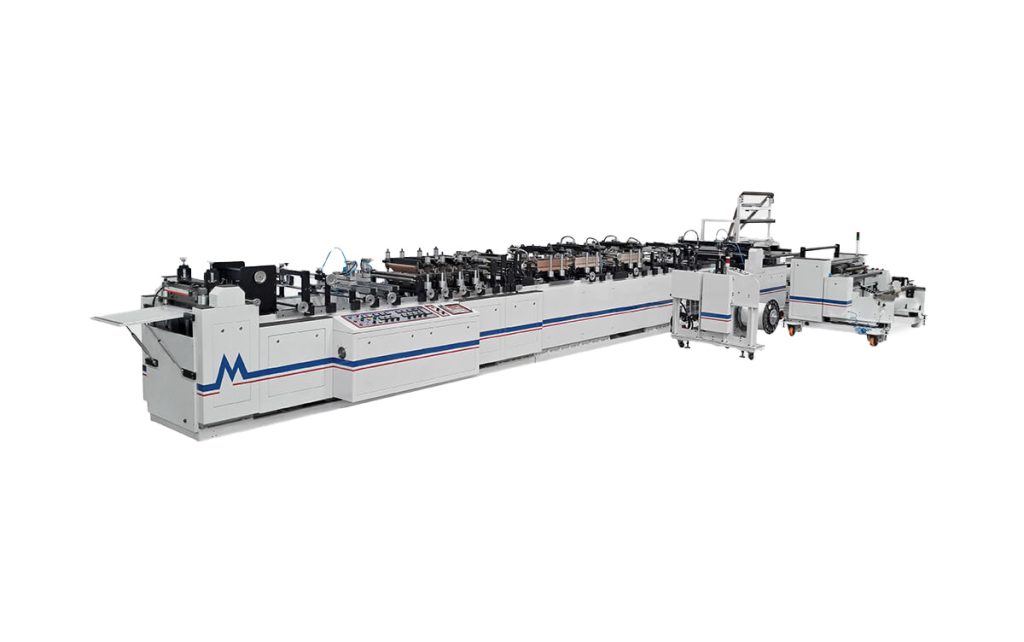

Mamata Win-500-PM

Mamata Win-500-PM is a machine with a unique combination of simplicity, flexibility, and performance. It is the only bag-making platform with the versatility to produce not only centre-seal bags and 2/3 side seal bags, but also Doypack bags, with or without zip, all on the same platform.

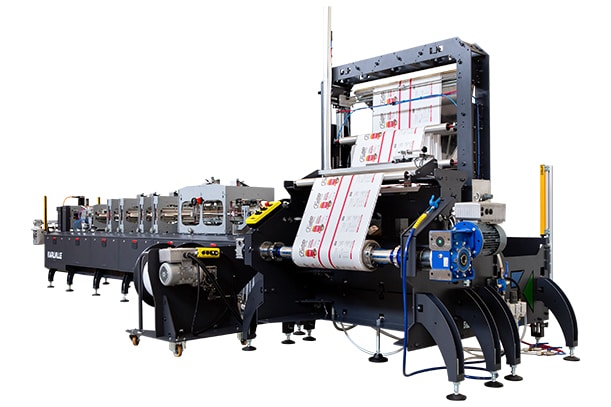

Karlville DSUP-400

A compact pouch-making machine designed for both digital and conventional production, with quick changeover, ideal for high-performance manufacturing of short and medium runs for standard laminations, monomaterials, and paper-based structures.

Mamata Vega 285

Vega 285-PM is specially designed to produce three-side seal bags and reinforced stand-up pouches in a single lane from PET/BOPP/Alu. laminates, among others. With a mechanical speed of 100 cycles per minute, it is a simple yet fast machine for converters with medium-scale production requirements.

PET FOOD

Mamata Win-610-PM

Win-610-PM has been specially designed with the emerging needs of the recyclable film processing market in mind, along with high productivity.

COFFEE BAG

Mamata Win-305-PM

The Win-305-PM is a high-speed central seal pouch-making machine for producing pouches with Fin Seal or Lap Seal, with or without side gussets.

BAG-IN-BOX

BIB 500 SL – TECNOCANTO

BIB-500-SL offers high versatility, performing the sealing of different film layers, inserting the spout and tap, marking data on the pouch, and carrying out cutting or perforation for pouch-by-pouch or continuous production in a fully automated process. With a single lane, it produces pouches with capacities ranging from 3 to 20 litres.

SPOUTS

STAND UP SPOUTS

NCA1604C

NCA1604C is an automated solution designed to weld plastic spouts onto flexible packaging with high precision and efficiency. Ideal for larger formats, it is suitable for applications such as beverages, jellies, soy sauce, flavourings, and cosmetic products like milk or facial masks.

STAND UP SPOUTS

NCA1620B-25

NCA1620B-25 is a fully automatic machine designed to apply plastic spouts to flexible packaging with high control and efficiency. It is ideal for larger formats such as beverage pouches, edible oils, juices, liquid detergents, and cosmetics.

SHRINK SLEEVE

SHRINK SLEEVE

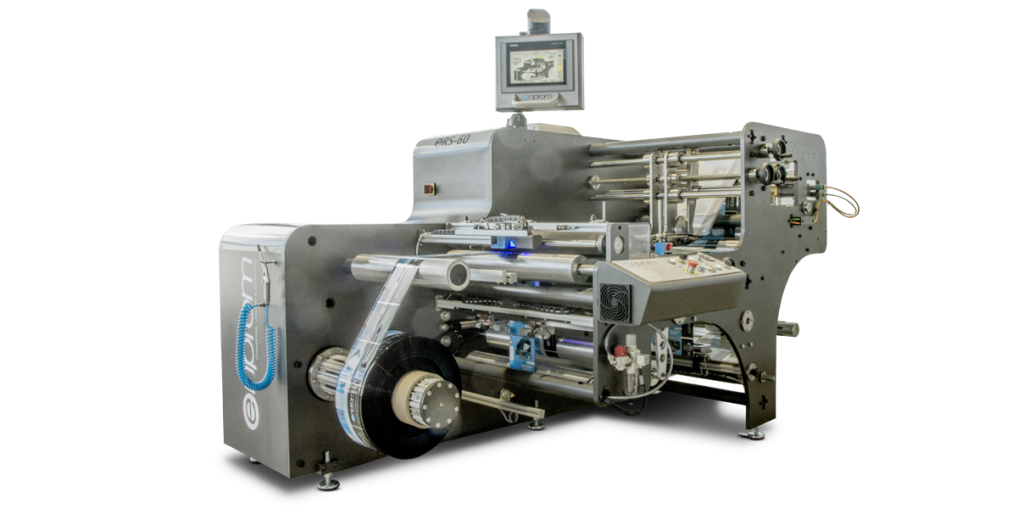

Enprom ERS-60

Emprom ERS-60 is a shrink sleeve seaming machine that converts a plastic sheet into a single sleeve label or multiple sleeves for promotional packaging, also known as sleeves. This equipment ensures a consistent and strong seal that will not open when heat is applied. The adhesive application allows for a flat and clean seam.